Online Testing solution

What is Online Testing?

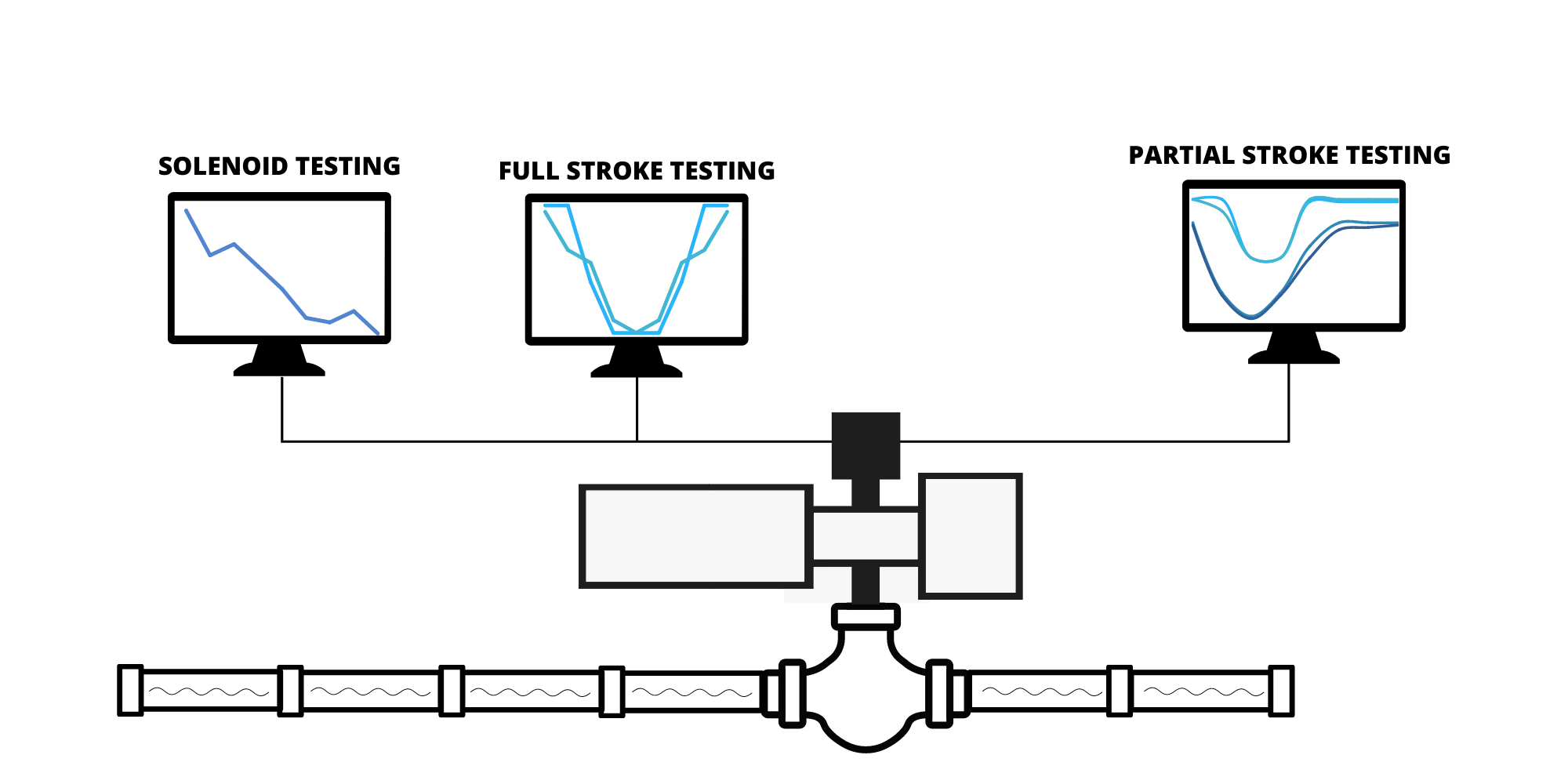

The purpose of online testing is to monitor and exercise the valves when they are in use. The advantage of Val Control's online testing solution is that the end-user can diagnose the valve while it is in use. Furthermore, the solution provides the possibility of comparing the current performance data with the optimal reference data. Val Controls online testing consists of Partial stroke testing (PST), full stroke testing (FST) & solenoid valve testing (SOV Testing):

- Partial stroke testing is used to test a certain percentage of shut down valves. The advantage of PST is that it allows operations to continue as the need to physically close the valve is eliminated.

- Full stroke testing closes the valve completely and is only used during shutdown or before installation.

- SOV testing is used to diagnose the solenoid valve. The test de-energizes the solenoid valve for a short period while measuring the pressure drop in the hydraulic or pneumatic system.

Online Testing solution

What is Online Testing?

The purpose of online testing is to monitor and exercise the valves when they are in use. The advantage of Val Control's online testing solution is that the end-user can diagnose the valve while it is in use. Furthermore, the solution provides the possibility of comparing the current performance data with the optimal reference data. Val Controls online testing consists of Partial stroke testing (PST), full stroke testing (FST) & solenoid valve testing (SOV Testing):

- Partial stroke testing is used to test a certain percentage of shut down valves. The advantage of PST is that it allows operations to continue as the need to physically close the valve is eliminated.

- Full stroke testing closes the valve completely and is only used during shutdown or before installation.

- SOV testing is used to diagnose the solenoid valve. The test de-energizes the solenoid valve for a short period while measuring the pressure drop in the hydraulic or pneumatic system.

Use case

Challenge

A company operating oil rigs in Europe are experiencing excessive downtime during the maintenance period of their oil rigs.

A lack of knowledge and planning of which parts needs to be maintained or replaced often leads to a prolonged downtime and increased procurement costs. They are therefore looking into various ways of reducing downtime and improve the planning process, with one of the areas being their various critical valves.

Solution

A part of the solution was to install Val Controls IDC24 online testing units at their critical valves which enabled them to perform partial stroke tests while the rig was running.

Furthermore, the online testing provided them with valuable information regarding the performance of the critical valves, with data being collected during the uptime of the rig. This data highlighted which parts needed maintenance or replacement enabling them to improve their planning- and procurement process and ultimately reducing the downtime.

Value

- Excercising the valves

An added benefit of the online testing procedure is that valves are exercised regularly. This reduces the risk of valve degradation caused by long periods of inactivity.

- Safety

Highlighting potential malfunctions before they happen will improve the overall safety score of the site.

- Time and cost savings

Being able to plan ahead and do predictive maintenance of the valves will improve the planning process and reduce the overall downtime.